One singular pain in the neck is having to tackle making a big hole in your work. Most drills will only accept bits up to 13mm in shank size, and frankly using a larger bit with a reduced shank would be terrifying in a hand drill. We're going to have a look at two bits that help with this issue: stepped drills and hole saws. There are of course auger, forstner, and spade bits too for drilling wood.

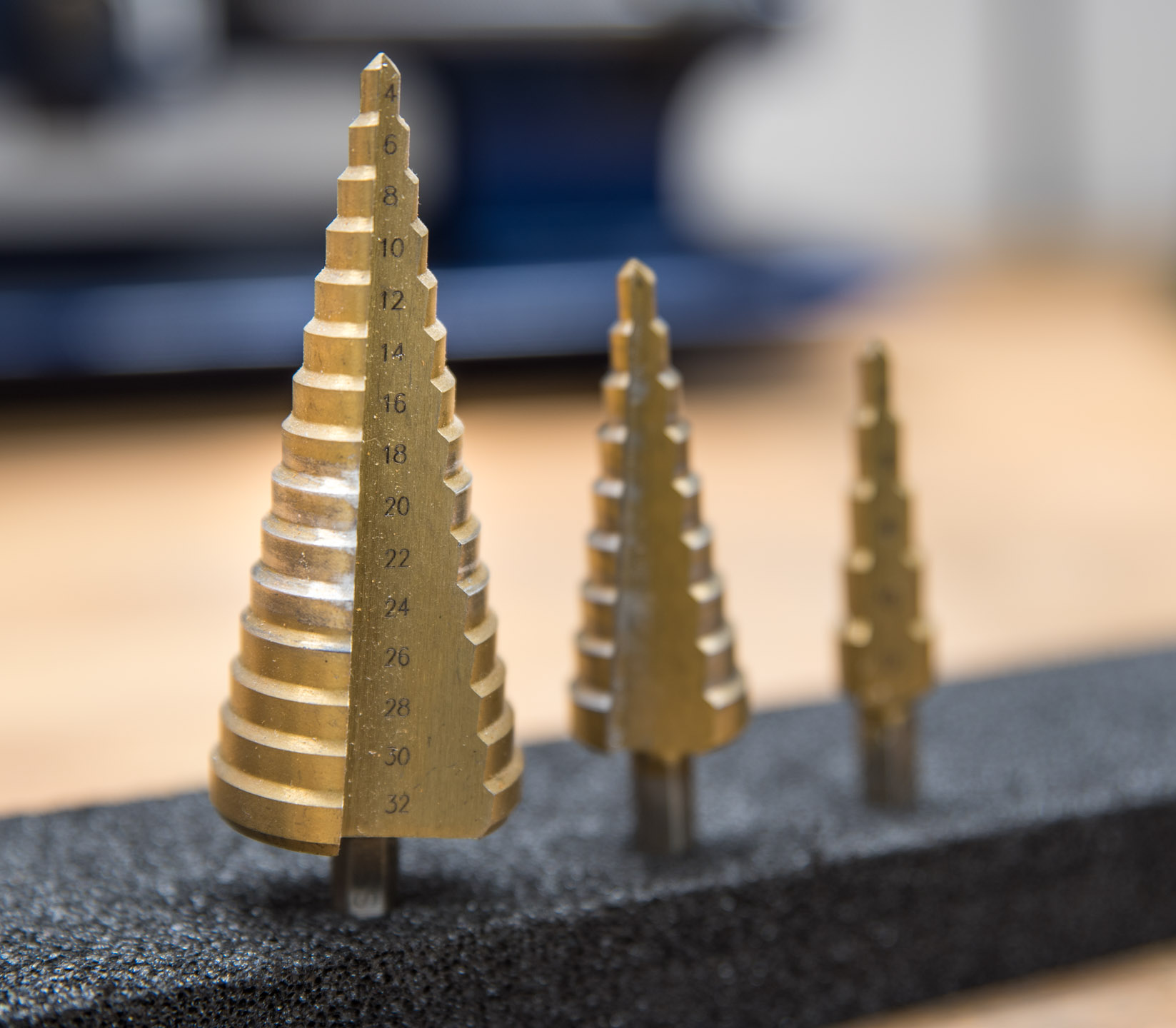

Stepped Drills

Looking like an accessory for piercing the heavens and punching the stars, stepped drills are fairly impressive, and they are also mighty practical. If your material is 4mm thick or less, stepped drills offer a a fantastic way for cutting large diameter holes. They're particularly good for materials like sheet aluminium and steel, where your alternatives are more often cutting the hole by hand with a saw.

Because stepped drills increase the hole size in increments, you can actually use them in a hand drill without much difficulty (my example is shown in a pillar drill), which makes them convenient for large holes in fairly awkward places, a fairly common issue when trying to add a new power switch or a drain port to a case for instance.

However, they do have a few major drawbacks. By incrementally expanding, these drills can get rather long, and if you have a 20mm hole to drill, that means a good chuck of the bit is going to poke through to the other side, which is not ideal in many cases. Another consideration is that they tend to increase in 2mm steps (or imperial equivalent), which can be awkward if you require a 19mm hole, say perhaps for a 19mm anti-vandal switch. The final main issue for me is that they don't play well with thicker materials. If you're working with 10mm-thick acrylic for instance, the material will be thicker than than the steps meaning you can't have a consistent hole sizing - you would want to use a different bit variety here.

Hole Saws

Like stepped drills, hole saws are pretty ferocious looking. Like their name suggests they're for cutting large holes, albeit in softer materials like wood or plastics. They're essentially a serrated collar that fits onto a standard sized drill bit in the centre: As the centre bit drills so does the collar cut.

The main advantage with hole saws is size. They can get rather large indeed, and they're a popular method for cutting 120mm holes for fans in materials like MDF or acrylic. That said, they have serious limitations also thanks to their design. You can all but say goodbye to using them on metal, whilst it is possible I simply don't recommend it, as there are better methods out there.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.